Dualshock 4 Analog Stick Drifting

The ii analog sticks decision-making role player movement and photographic camera controls feel maximum wear. Not surprisingly, controller drift caused by failing joysticks or thumbsticks is the well-nigh common reason for PlayStation four owners to discard their DualShock 4 controllers.

Nonetheless, at that place is a way to supplant the analog sticks for a tiny fraction of the price yous would have to pay for a new controller. Read on to find out how to fix PS4 controller drift and learn the best soldering and desoldering practices while we are at it.

You Might Not Demand to Desolder Everything

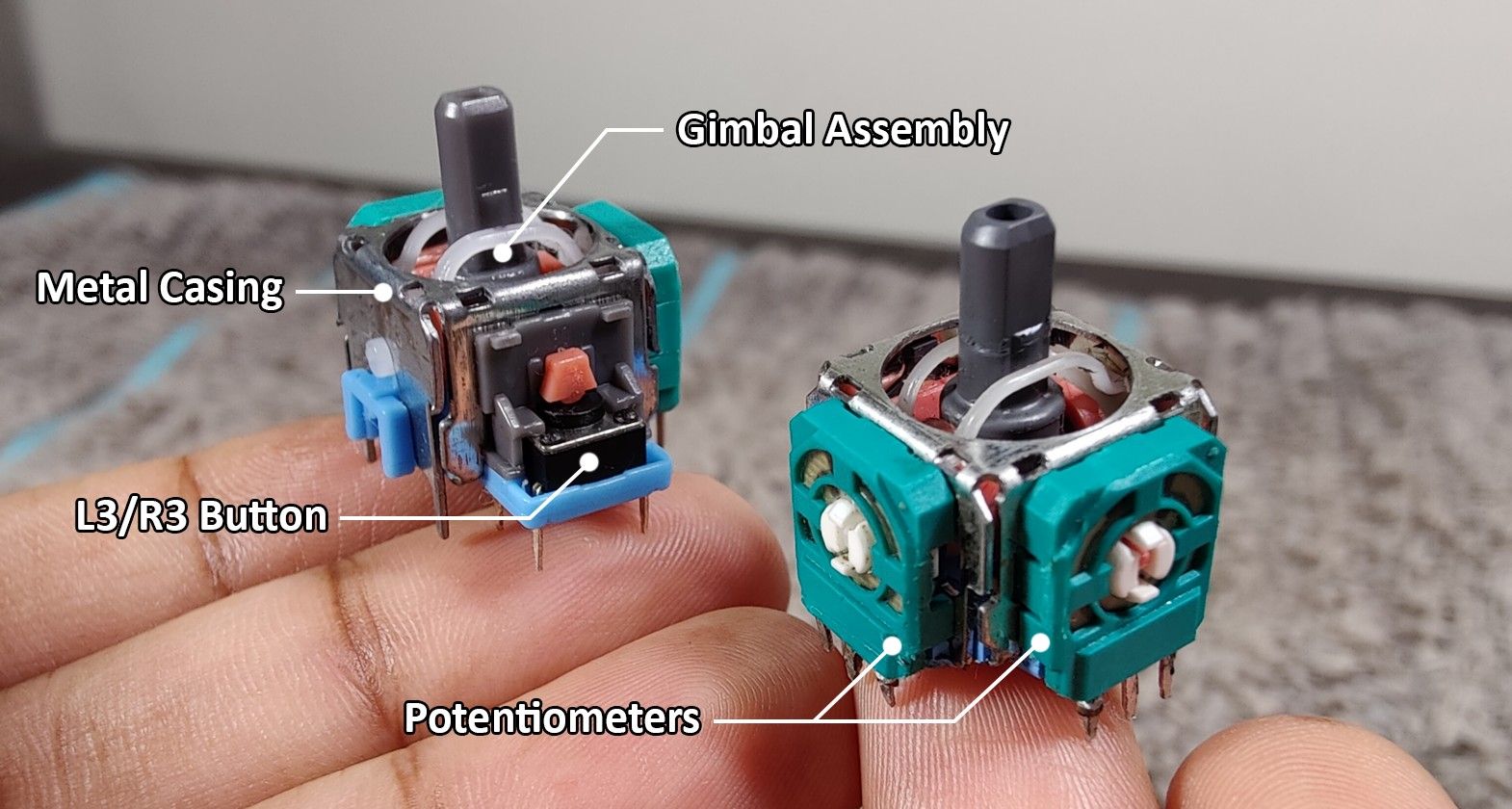

The Alps Alpine branded analog sticks used in DualShock four wireless controllers can be split into iii discrete components for the context of this repair: the main housing and 2 potentiometers. The former contains a spring-loaded joystick constrained along a two-axis gimbal mechanism.

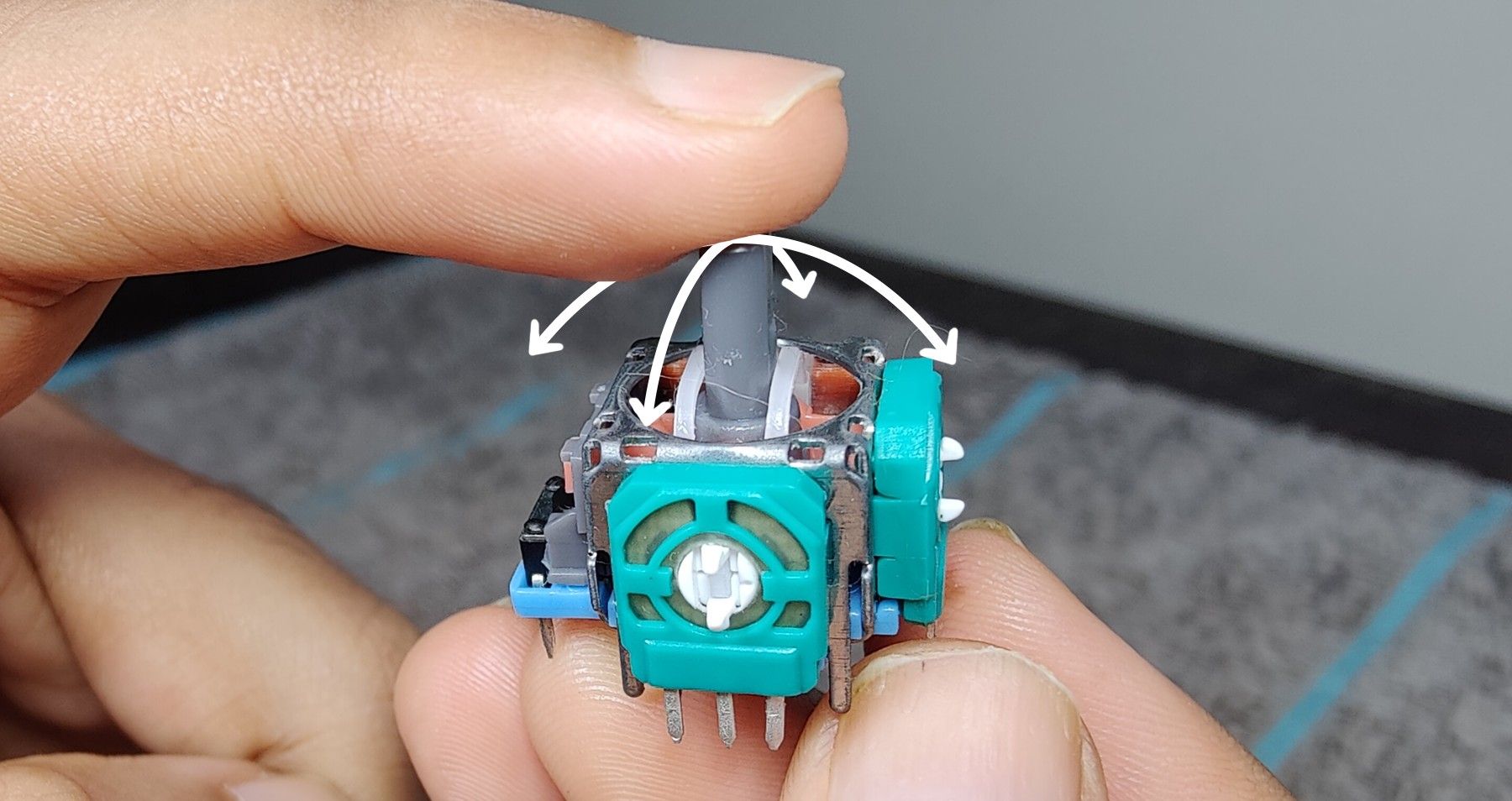

The loss of leap tension in this gimbal associates is ane of the two primary contributors of controller drift. The joystick will not return to the center position as the springs deteriorate over time. This tin be verified by checking for play in the machinery.

Excessive play allows the joystick to be moved more than than a few degrees off-centrality before you tin can experience return pressure level from the springs. Controller migrate occurs when this axial play increases across the preset expressionless-zone threshold of the sensors.

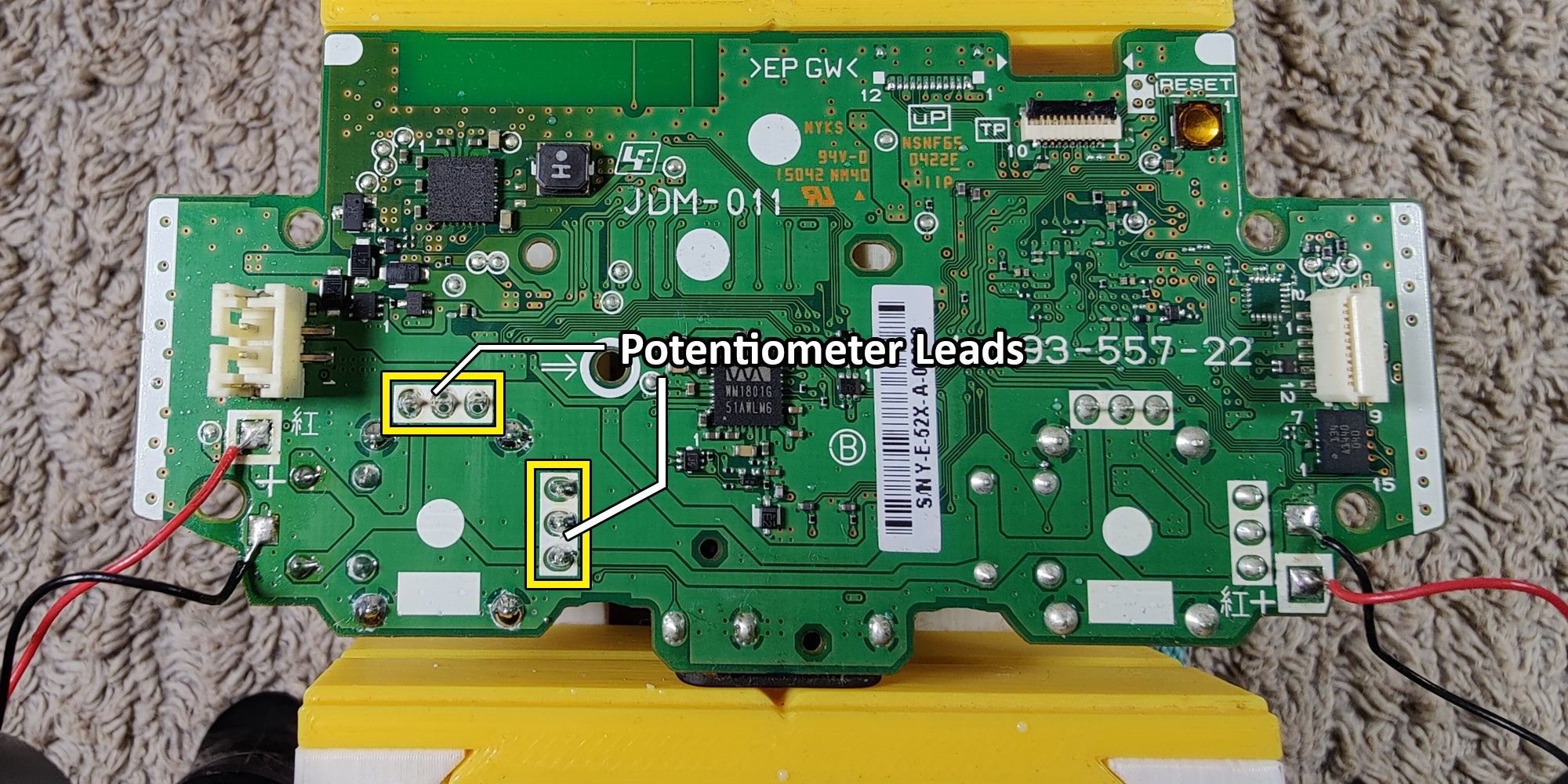

These sensors, or potentiometers to exist precise, bring us to the remaining two physically distinct pieces of the analog stick assembly. Moving the joysticks rotates the two potentiometers, which tape joystick movement forth the Ten and Y axes. These components are the culprits in an overwhelming majority cases of controller drift.

Potentiometers interpret rotational motility into voltage signals by sliding ane electrically conductive piece of metal beyond another ane. This high-friction affair eventually wears out these sensors until they output faulty signals, which manifest every bit controller migrate.

What's the indicate of this engineering science lecture?

Well, now nosotros know that the entire analog stick module must be replaced if at that place is excessive play in the joystick gimbal associates. If that isn't the case, you are better off replacing simply the potentiometers. The latter, as you lot'll run across in due course, is significantly easier than the former.

The entire analog stick module must also be replaced if y'all're experiencing problems with the L3/R3 buttons. That's a mistake with the momentary push-button switch permanently fused with the chief housing.

Yous tin purchase an entire analog stick module or purchase the potentiometers separately. Please note that these are Chinese knock-offs of Alps parts. Original replacements (part number RKJXV) can be purchased from reputed sellers such as Mouser Electronics.

What's Needed to Repair the PS4 Controller

You lot'll need a Phillips head screwdriver with the tip size of #00 in add-on to a plastic pry tool or an expired credit card to disassemble the DualShock 4 controller. A good pair of precision tweezers aren't mandatory, but they volition make your life easier. Yous might also need flush cutters while desoldering the entire analog stick assembly.

Soldering and desoldering the components onto the controller'due south printed circuit board (PCB) requires some form of piece of work holding. Panavise makes neat PCB vises, but y'all tin salvage a lot of cash by opting for a 3D printed vise instead. You lot tin even MacGyver some Play-Doh into a makeshift PCB-holder.

However, we strongly recommend against cutting corners with soldering equipment. The datasheet for Alps analog stick modules recommends soldering at a maximum of 660°F for no more than three seconds per soldered articulation. Overheating these components will either destroy them outright or crusade them to fail prematurely.

If you don't own a decent temperature controlled soldering station, we recommend a combination of PINECIL soldering atomic number 26 and a 2.4mm chisel tip (D24) paired with a charger or power depository financial institution capable of USB PD. For an investment that will final you a lifetime, the Hakko FX-888D is a terrific soldering station for the money. Don't forget to buy a compatible chisel tip, because that tip geometry makes soldering such plated through-hole (PTH) joints easier.

We recommend the Engineer SS-02 vacuum pump for desoldering. Some prefer a desoldering wick, but that'due south more appropriate for SMD soldering and necessitates longer dwell times compared to a vacuum pump. Never inexpensive out on solder wire. Kester'due south 63/37 (0.02 inch) atomic number 82 solder will make your life much easier and soldering reliable.

A good "no clean" flux dispensing pen lends itself to crafting perfect solder joints. Finally, you will need some high-purity IPA to clean the PCB once y'all're done. Either a brass tip cleaner (recommended) or a moist soldering sponge (avoid regular ones) is besides indispensable for soldering success.

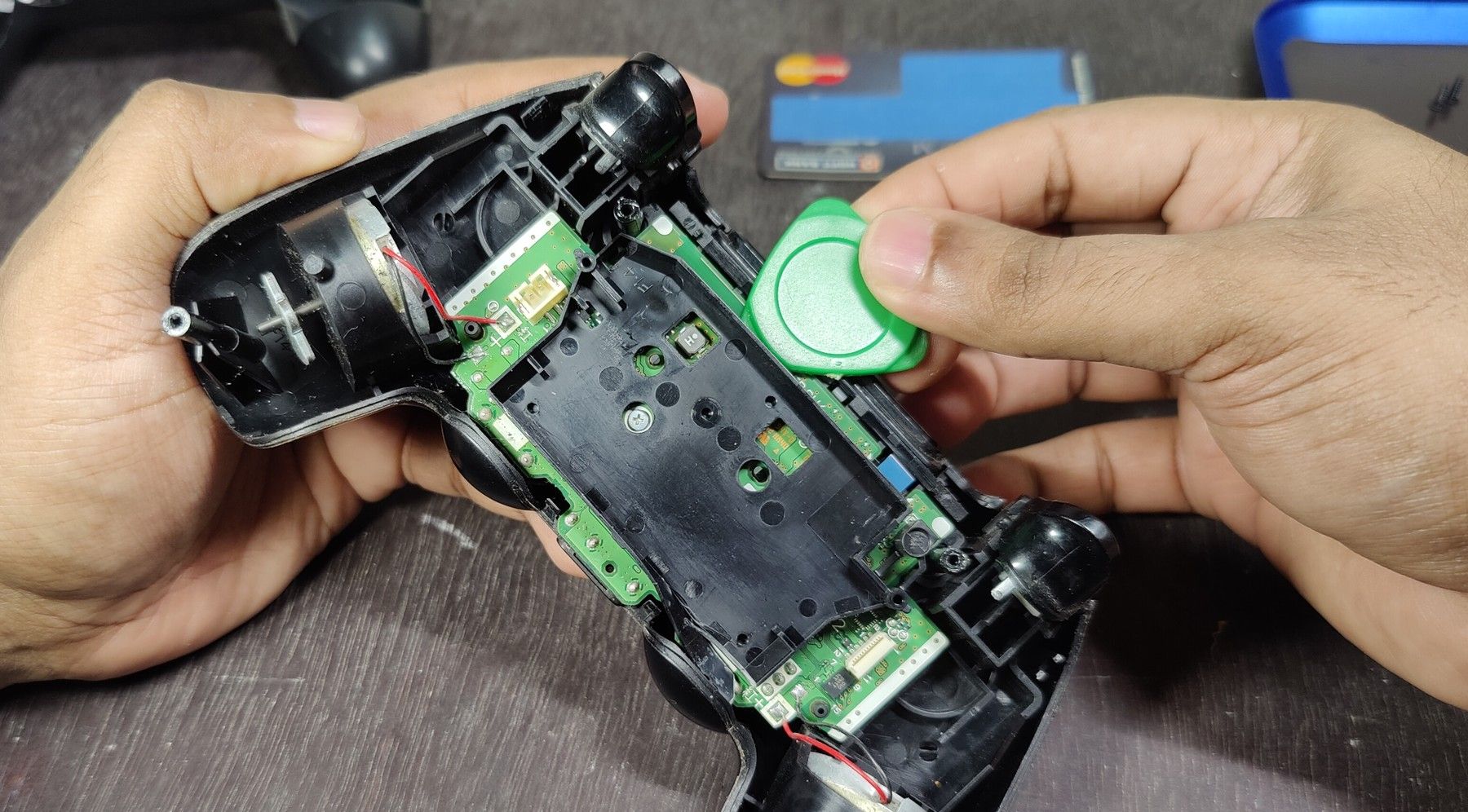

Step 1: Disassemble the DualShock 4 Controller

Controller disassembly has already been covered in our DualShock 4 battery replacement guide. Follow that guide earlier proceeding to the next step.

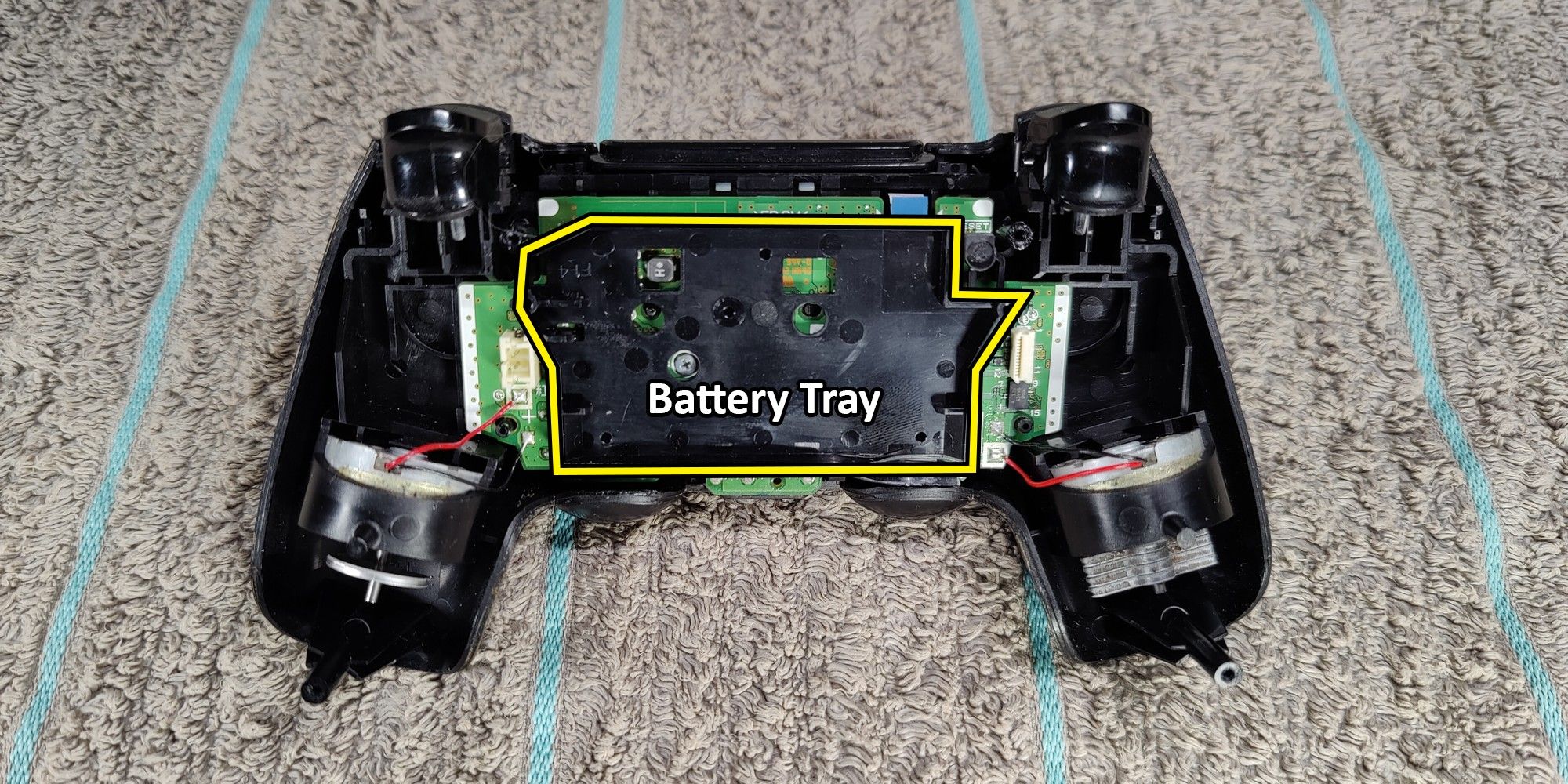

Step 2: Remove the Battery Tray

The battery tray isn't fastened down, so you can either use a plastic pry tool or your fingers to lift it off the four retentiveness posts to expose the mainboard.

It is at present possible to desolder the components without physically separating the mainboard any farther. Skip to Step vi if you prefer to go on the mainboard assembly intact.

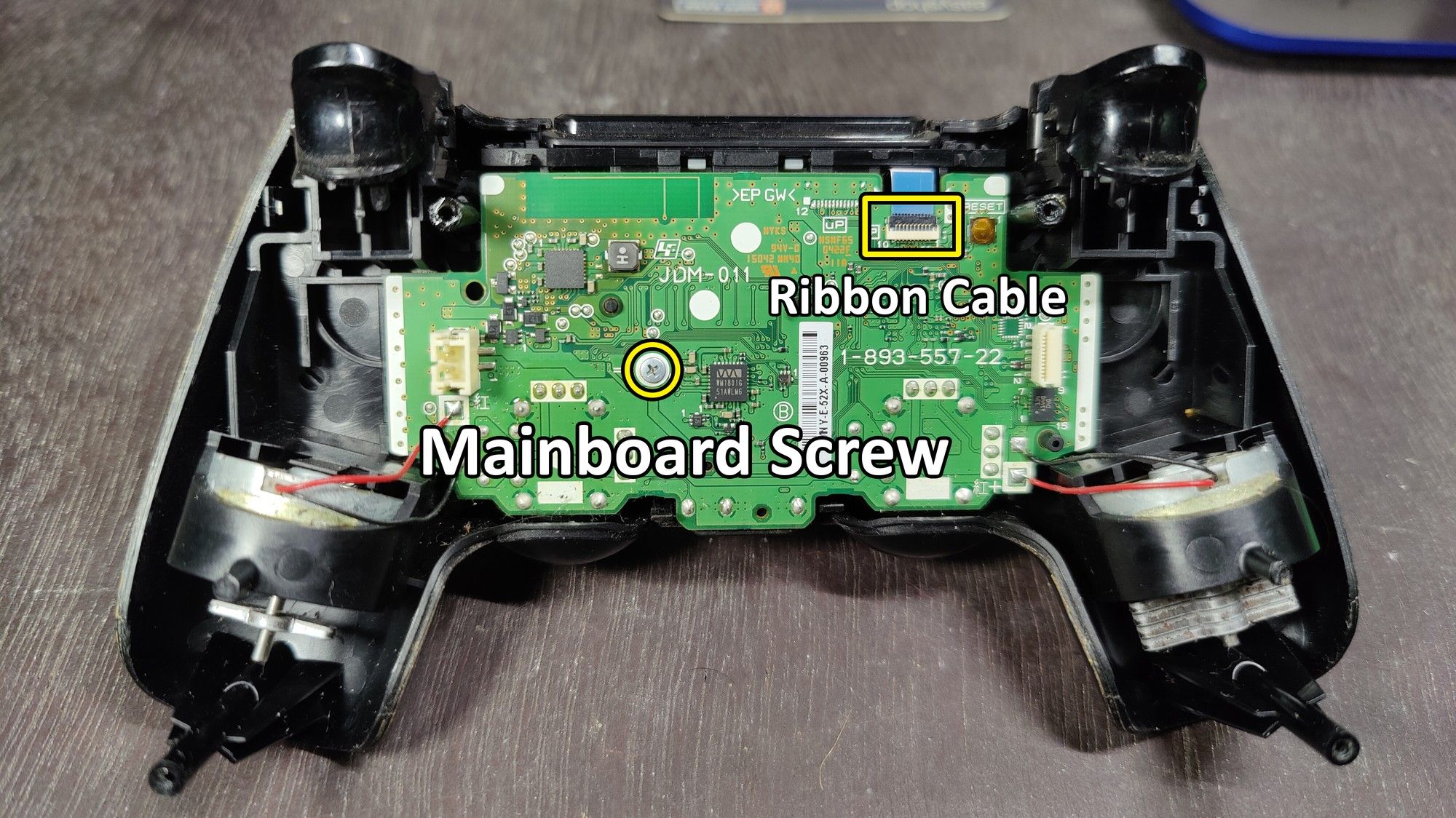

Step 3: Unscrew the Mainboard

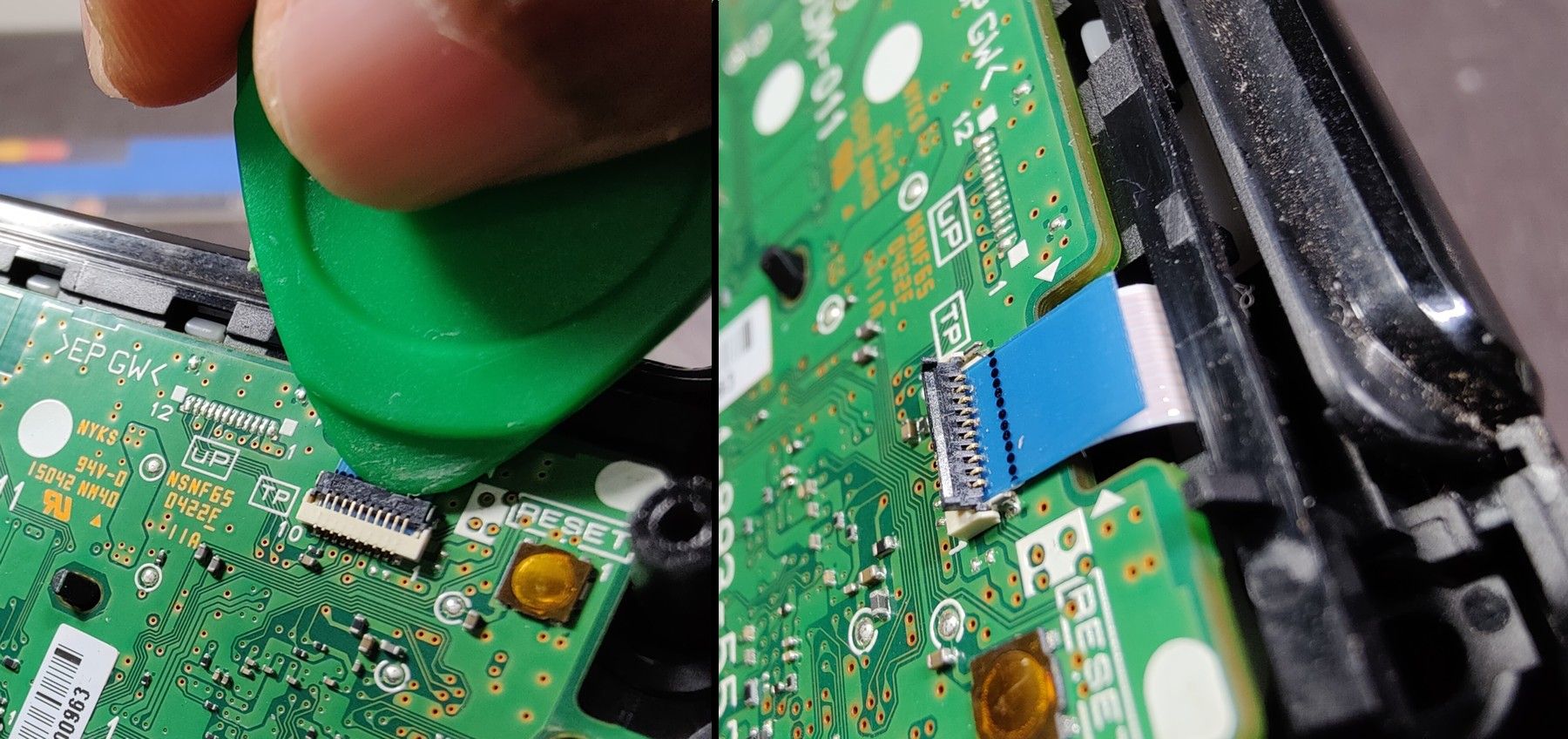

A lonely screw and a ribbon cablevision connecting information technology to the touchpad must be removed before you can take the mainboard assembly off the top half of the chassis. Use your fingernail or a plastic pry tool to rotate the blackness cable retentiveness machinery by 90 degrees into the open position.

You can now pull the cablevision out using the bluish pull tab. It is now safe to undo the screw anchoring the mainboard assembly.

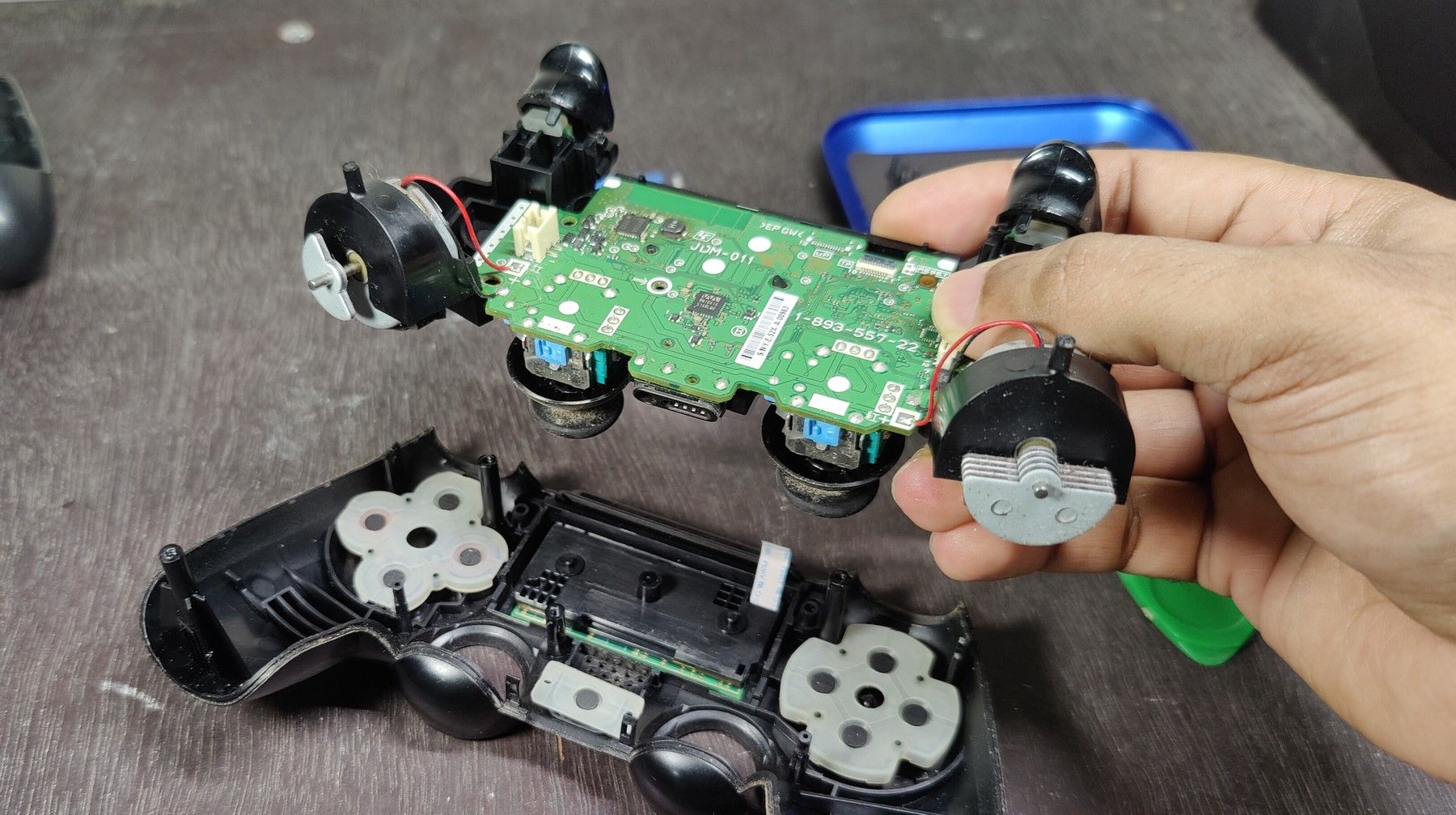

Step 4: Separate the Chassis and Mainboard Assembly

Flip the controller upside downward and carve up the mainboard associates from the top half of the chassis. The friction-fit buttons and contact pads in the top half of the chassis may driblet nether gravity, so exercise caution while handling it.

You tin now pop off the plastic thumbstick covers/grips to expose the analog stick modules.

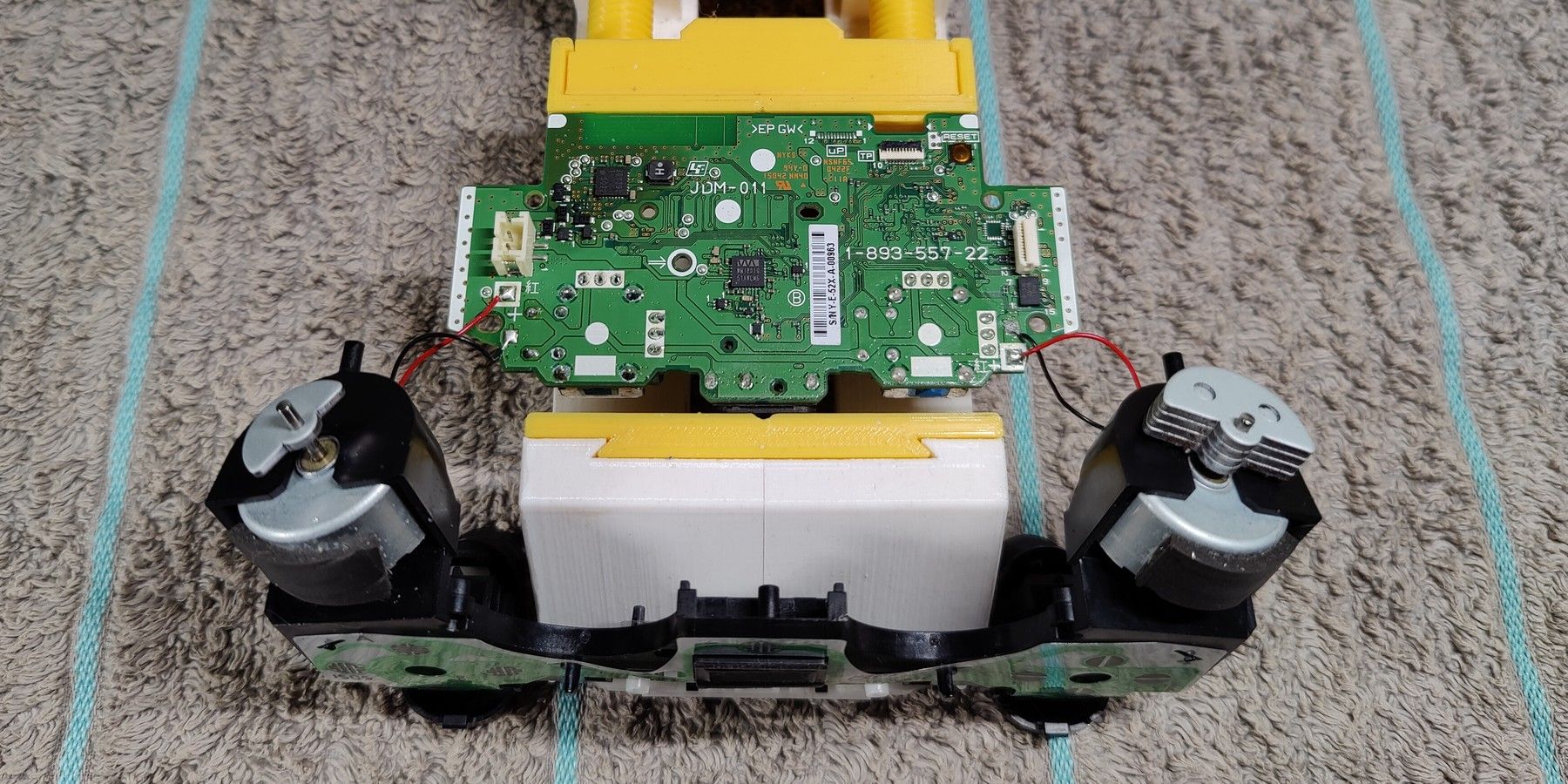

Step five: Isolate the Mainboard

The mainboard can now exist slid off the alignment posts and separated from the rest of the assembly housing the index triggers and vibration motors.

Be gentle to avoid breaking the motor wires. Even if you lot brand a mistake, the wires are most likely to popular off the pads on the mainboard. Resoldering them is a trivial matter.

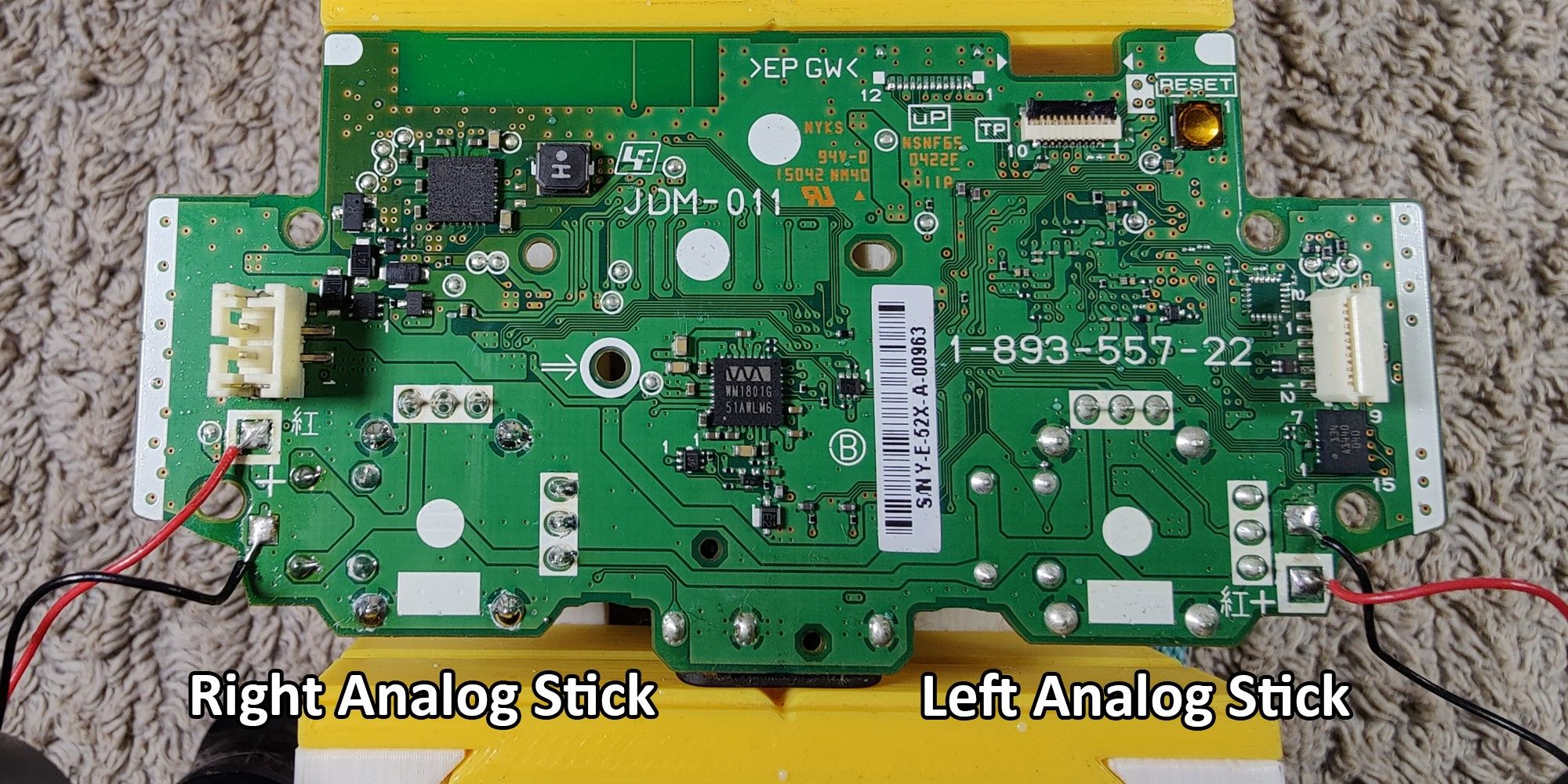

Step 6: Mind the Perspective

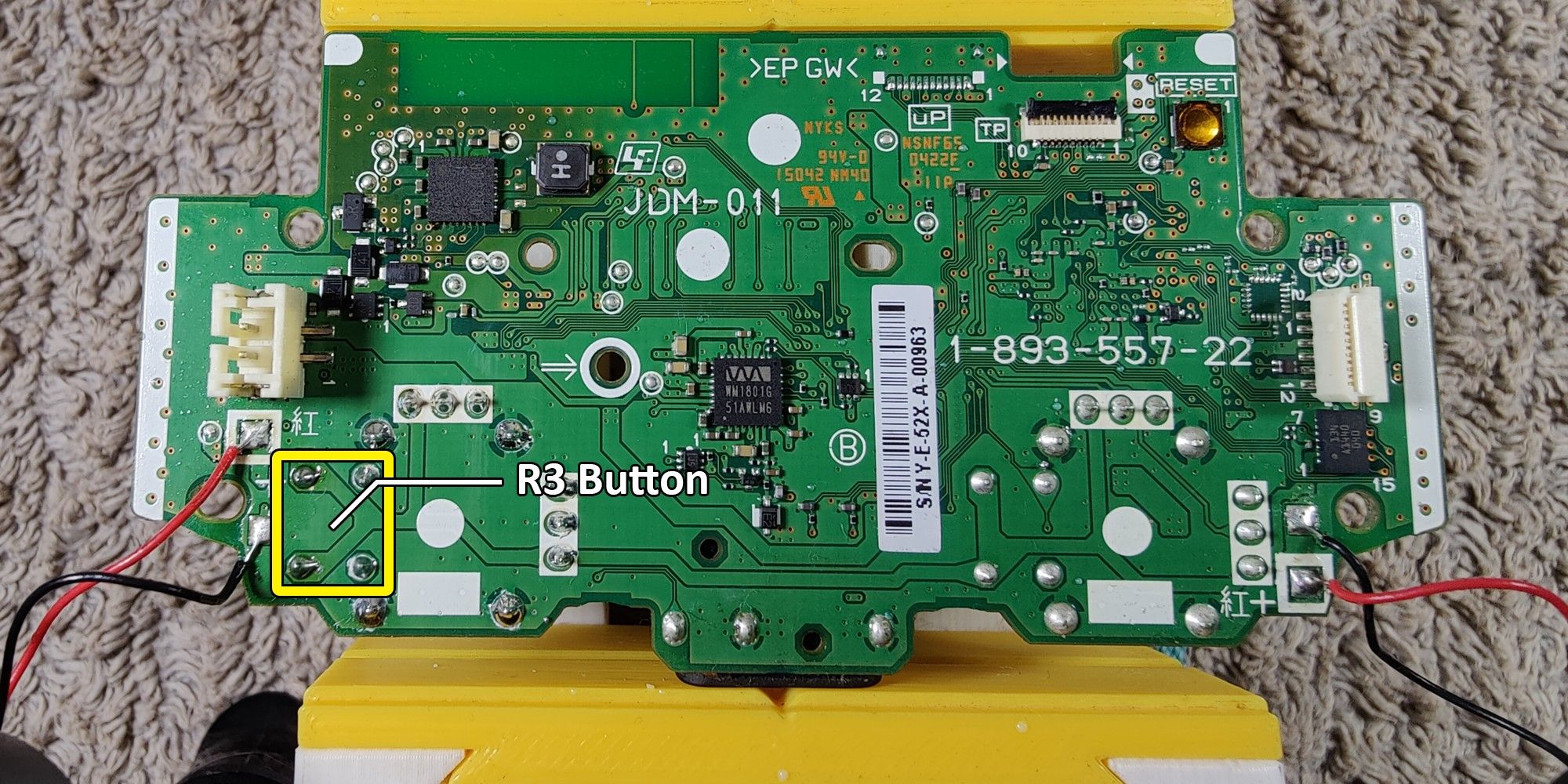

If you plan to desolder a single analog stick, brand sure you choose the correct ane. You lot'll be looking at the PCB from the rear, then the positions will be mirrored horizontally.

The appropriate joints meant to be desoldered will be highlighted henceforth. Y'all just demand to desolder the potentiometers if y'all don't plan on replacing the entire analog stick assembly.

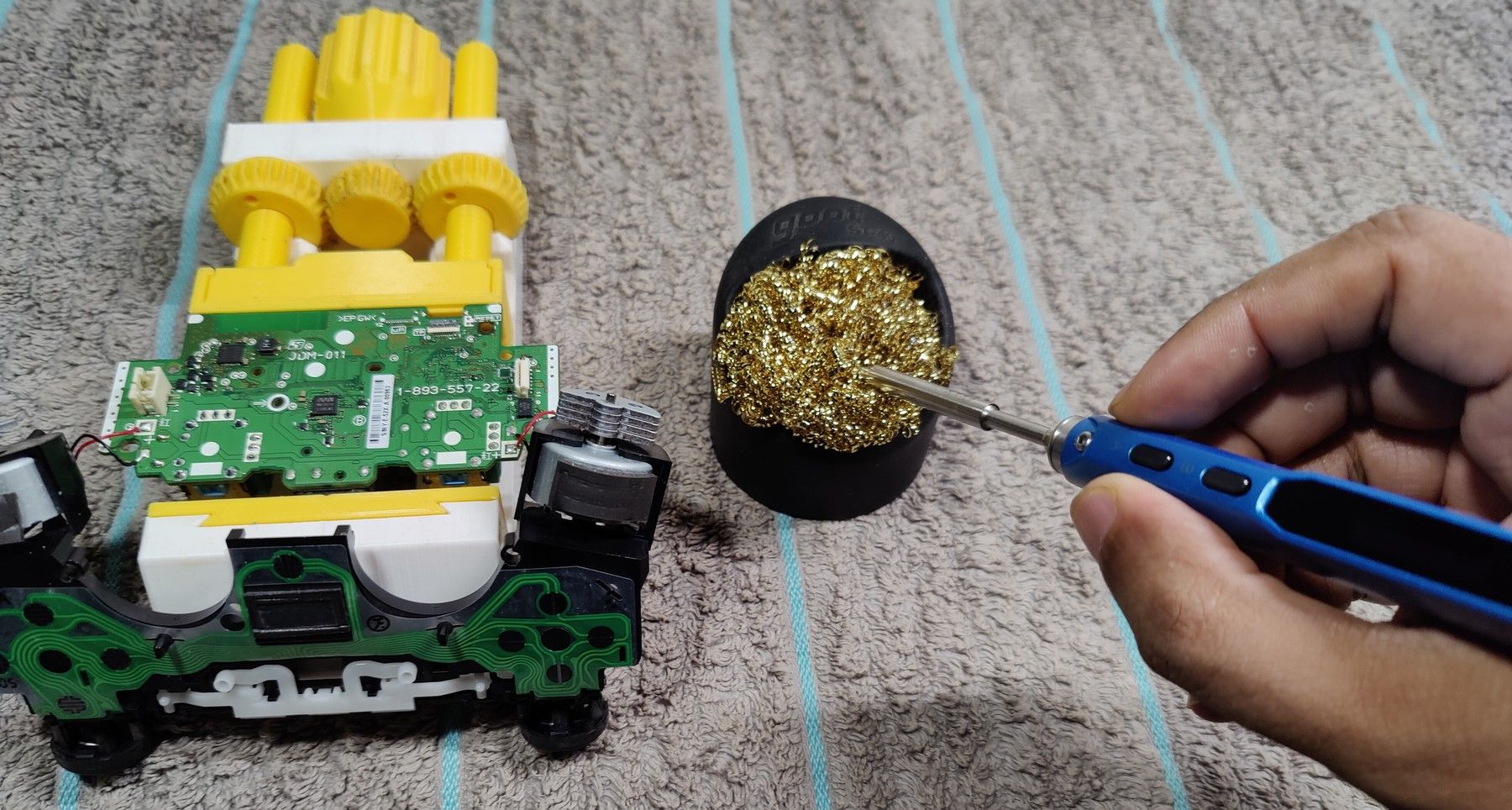

How to Succeed at Desoldering

We recommend using a desoldering pump rather than desoldering wick/braid because the latter is more advisable for SMD soldering work. The braided copper significantly increases the thermal mass of the joint, which leads to longer dwell times and consequently increased risk of PCB delamination and/or lifted pads.

The copper braid relies on capillary action to gradually wick away solder. The desoldering pump, however, instantaneously sucks molten solder out of the articulation.

The process of soldering and desoldering becomes impossible when your components and/or the tips suffer from oxidation. The hot soldering iron tip besides begins to oxidize when exposed to air. The oxide layer acts as an insulator and prevents the tip from heating the joints. Adding extra flux on the joints chemically scrubs them clean.

Removing oxidation involves blanket the tip with fresh solder and and then wiping it off in either the contumely tip cleaner or a slightly moist (not wet) sponge. The refreshed tip will announced shiny and conduct heat ameliorate. Repeat this procedure periodically to maintain thermal efficiency.

Stride 7: Desoldering Potentiometers

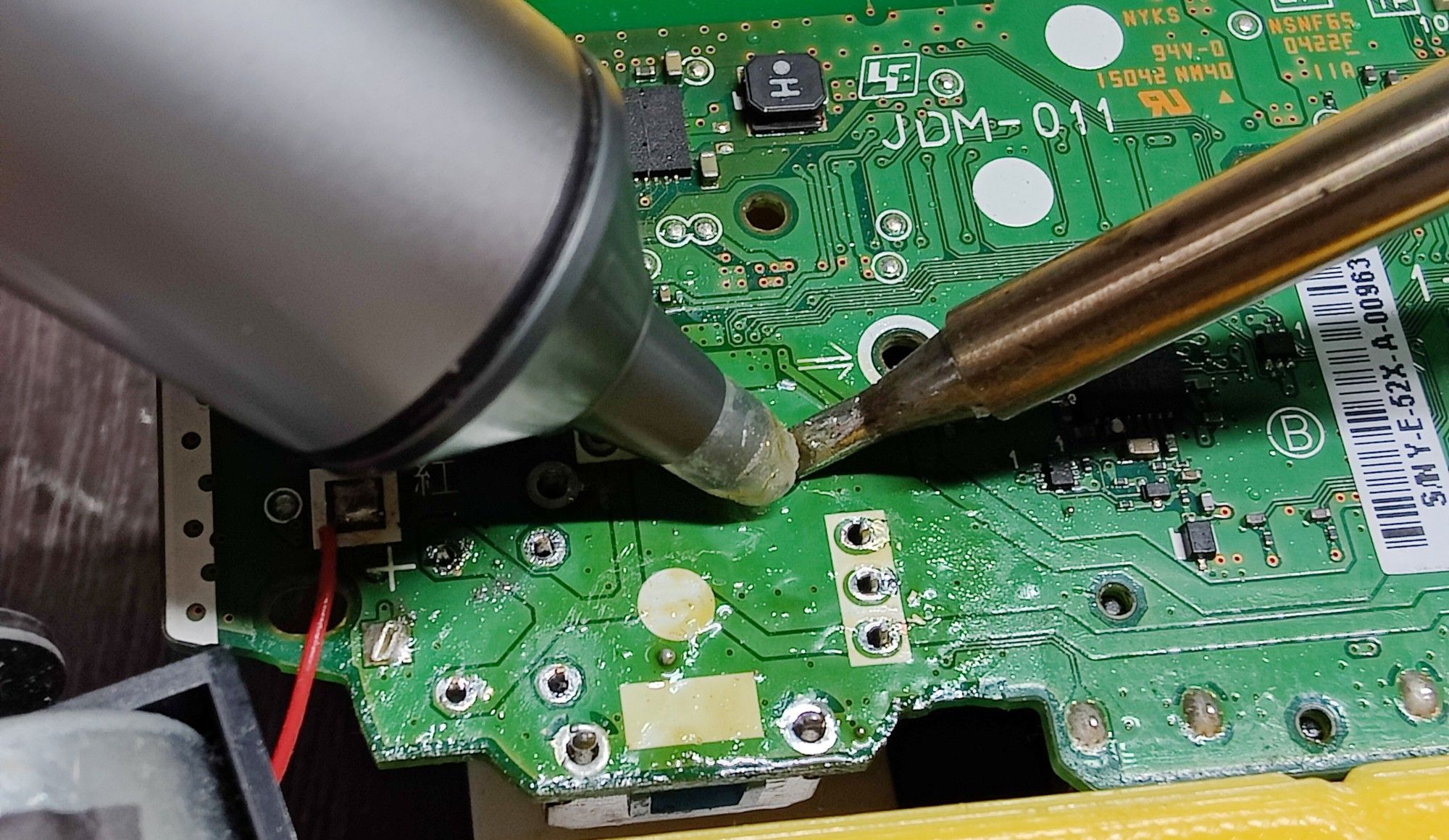

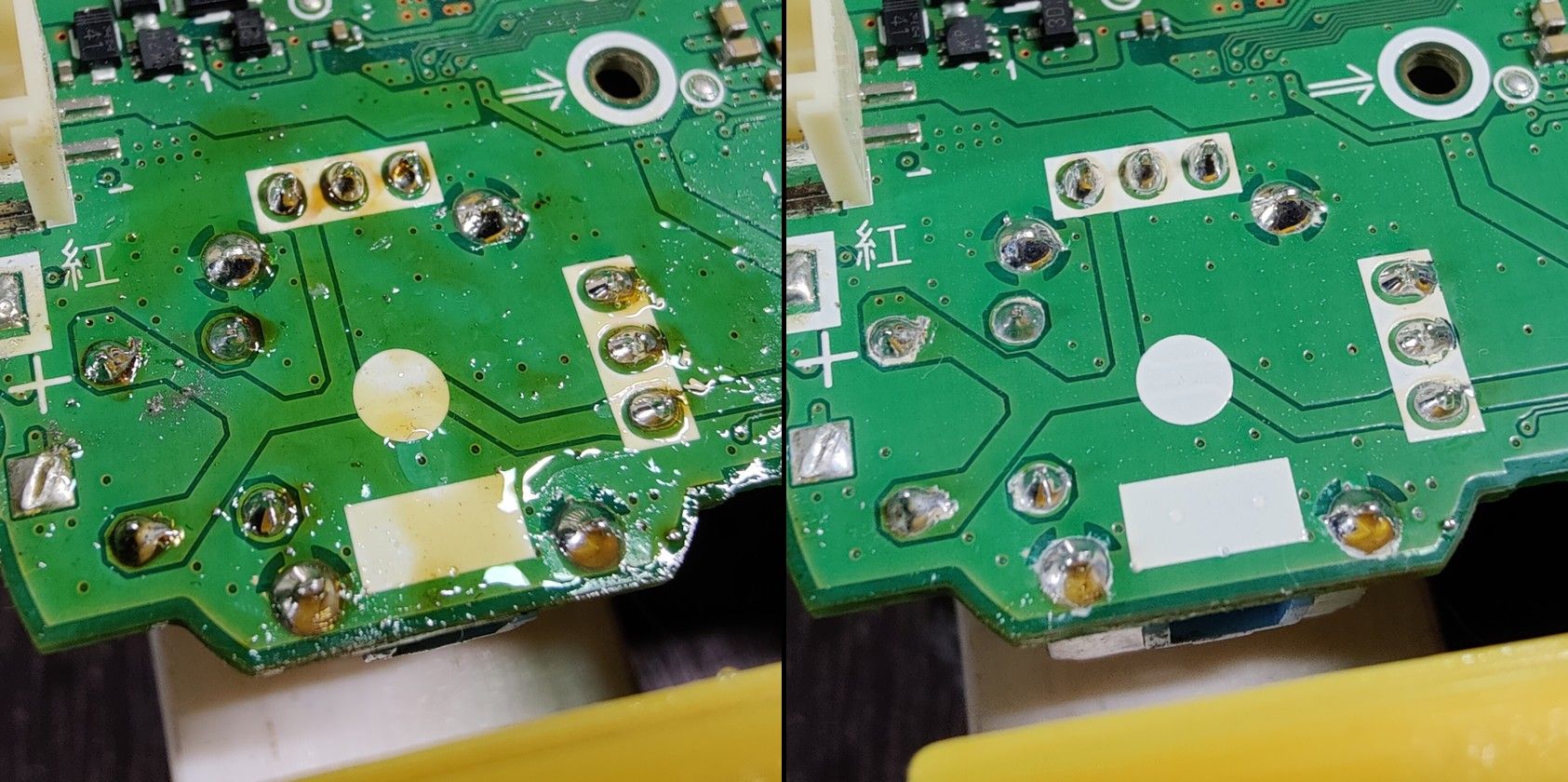

Utilise a generous blanket of flux to every joint meant to exist desoldered. Ready the soldering atomic number 26 to 660°F and bring the tip to the joint. Once the solder has melted into the consistency of a sticky liquid, embrace the unabridged joint with the tip of the desoldering pump without removing the soldering iron's tip. Press the release trigger to vacuum abroad the molten solder.

The original solder is of the nasty lead-complimentary multifariousness, which involves some noxious chemicals. A smoke extraction organisation in a well-ventilated room is good for your lungs. The factory solder also doesn't flow well, so you about likely won't succeed in your first few attempts.

Bridge both the circular pad and the potentiometer atomic number 82 with the iron tip and add fresh lead solder to the articulation. While this may sound counterintuitive, you are gradually replacing the nasty lead-free solder with easy-flowing lead solder.

A full joint also allows the pump to create a vacuum seal that enhances suction.

Afterward a couple of attempts, you should witness a gaping void between the potentiometer lead and the round pad surrounding it. Repeat this for the two remaining leads and you are ready to extract the potentiometer.

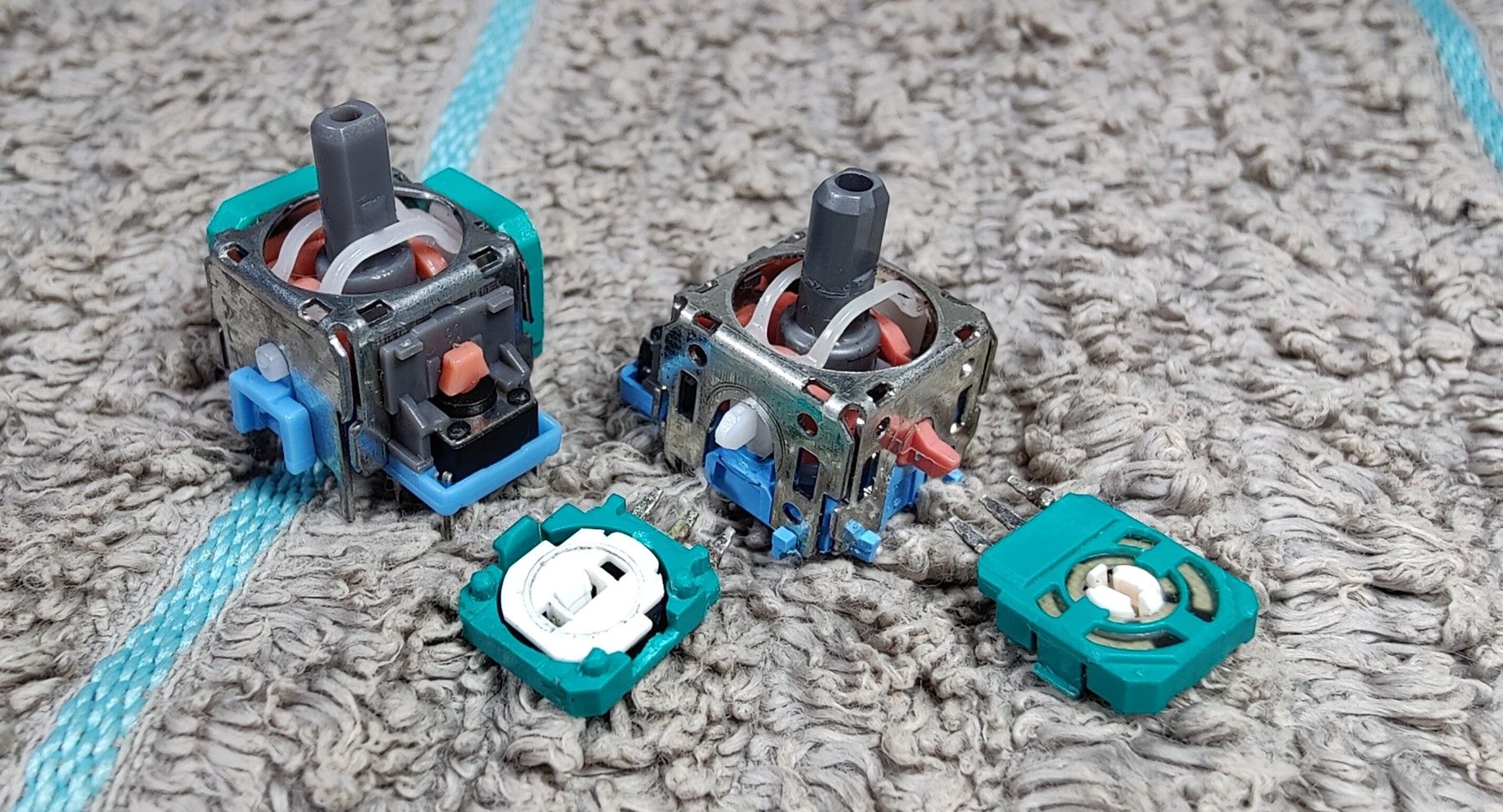

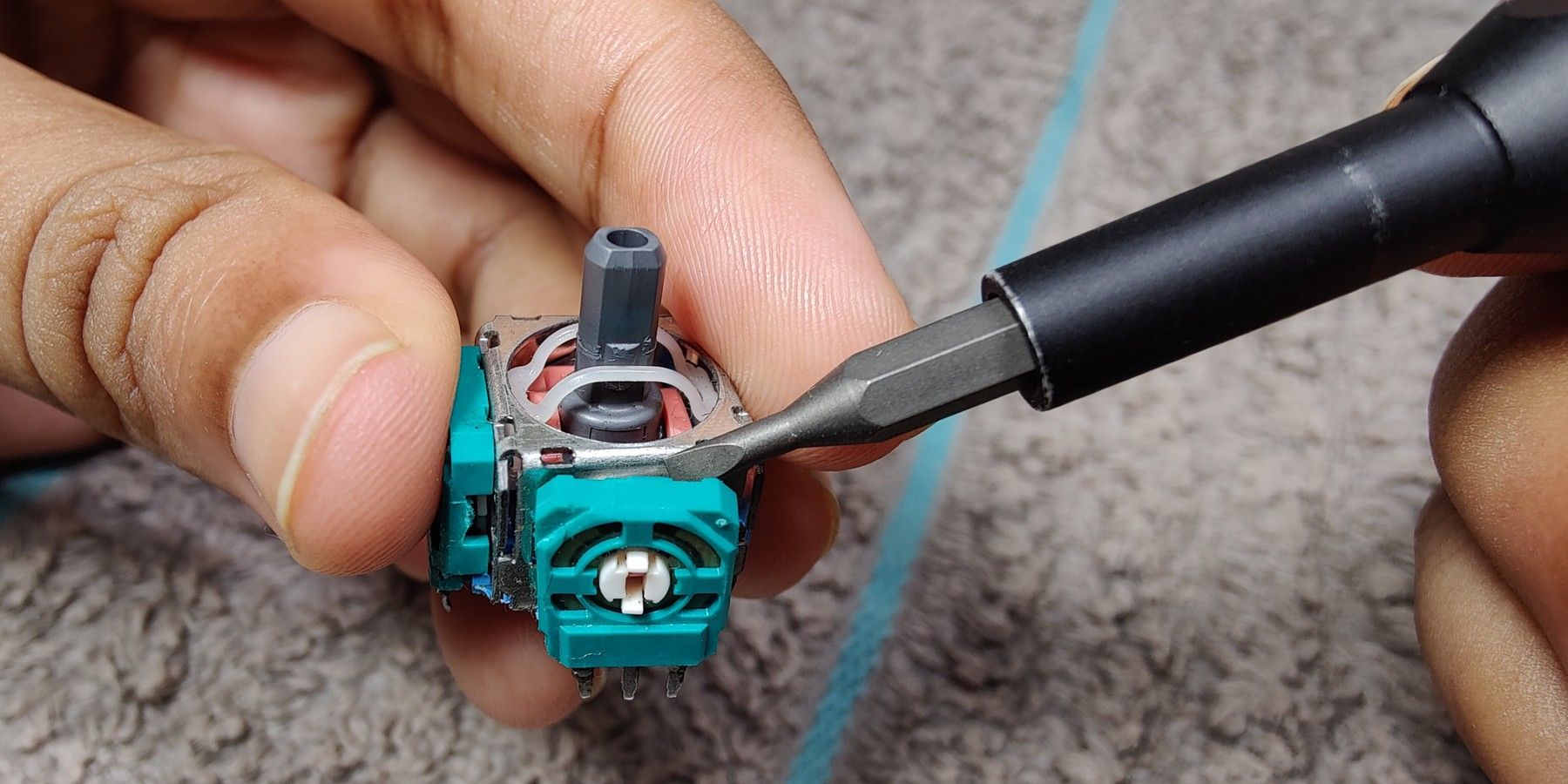

Footstep 8: Carefully Pry off the Potentiometers

Flip over the PCB to pry the potentiometer from the primary analog stick housing. The module should come off easily. Don't attempt to force information technology out if it's stuck, because that tin elevator a pad. A tiny sliver of solder might be belongings dorsum one of the leads. Heating the offending pad with the soldering fe should release information technology.

Repeat this process for another potentiometer. Skip to Stride 13 if you but demand to replace the potentiometers.

Step 9: Desolder the Momentary Button-Push

Echo the aforementioned desoldering process for the L3/R3 button. However, information technology can't be separately removed like the potentiometers since it's permanently integrated into the main housing.

Footstep 10: Thermally Isolate the Structural Joints

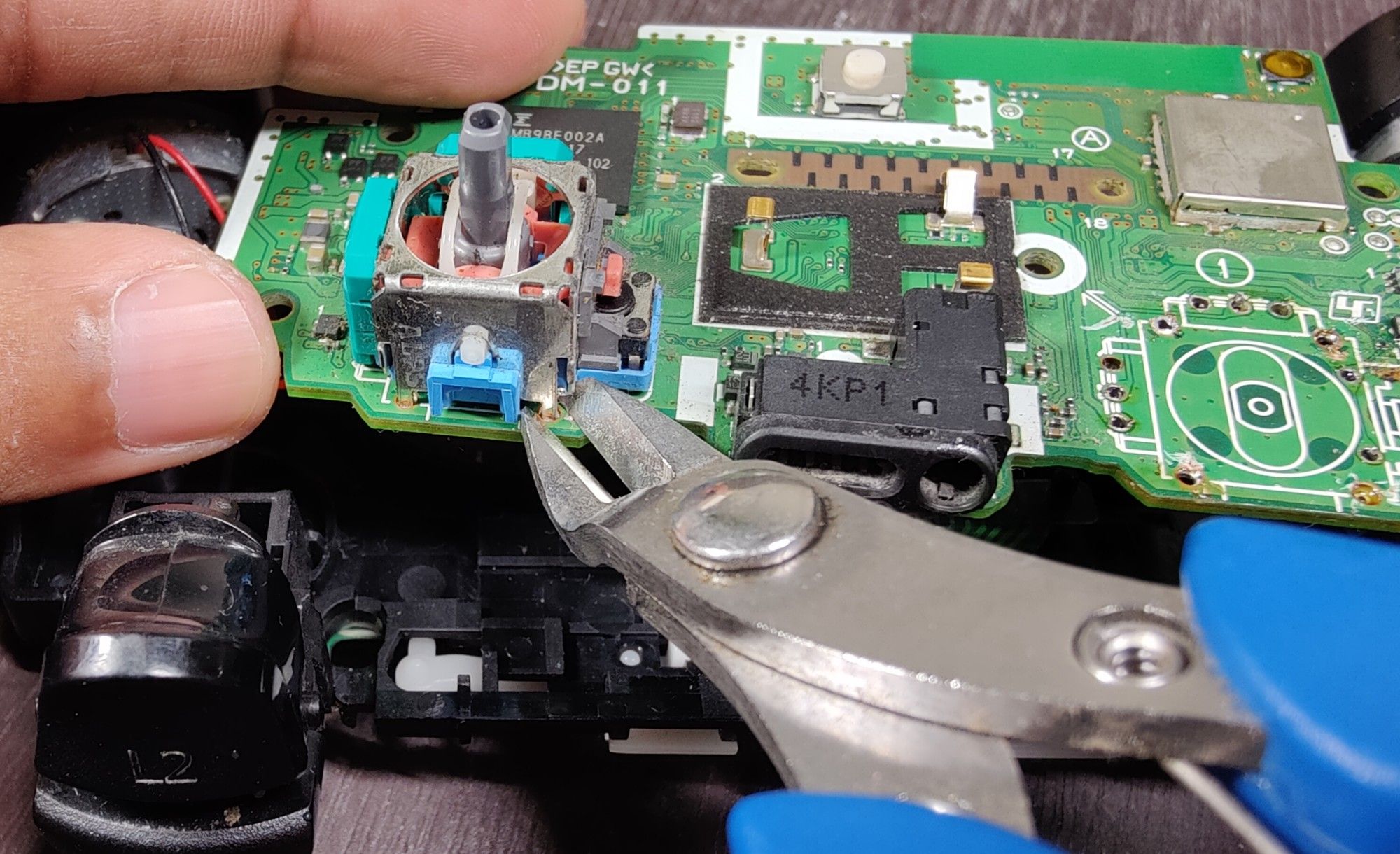

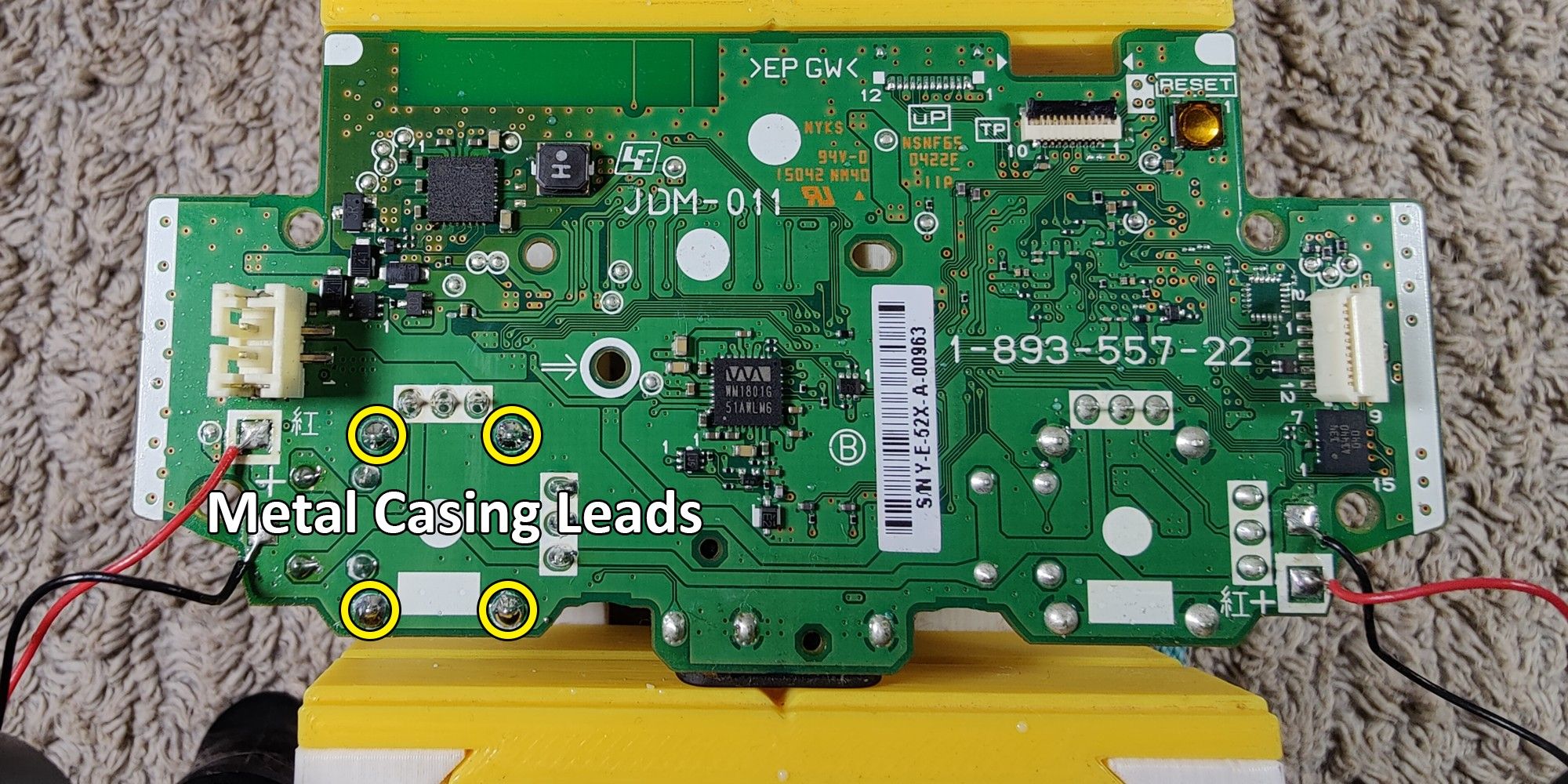

Just four soldered joints stand between you and success, just these are nearly impossible to solder unless yous take access to loftier-wattage JBC, Pace, or Hakko soldering stations.

These are structural joints meant to securely anchor the analog stick to the PCB. This has the unfortunate side-effect of introducing the tremendous thermal mass of the metal casing housing the gimbal associates.

These joints act similar massive heatsinks, so regular soldering irons cannot supply enough power to maintain the minimum tip temperature necessary to melt solder. This necessitates inordinately long dwell times which, in plough, increases the gamble of PCB delamination and/or lifted pads.

If the solder doesn't cook inside iii to 4 seconds, flip over the PCB and use sturdy flush cutters to sever these leads from the metal trunk from the contrary side. This volition significantly reduce their thermal mass and make soldering easier.

Step 11: Desolder the Structural Joints

With the soldering difficulty reduced from Dark Souls to Roblox, even the most basic soldering irons can at present exist used to desolder the final four joints.

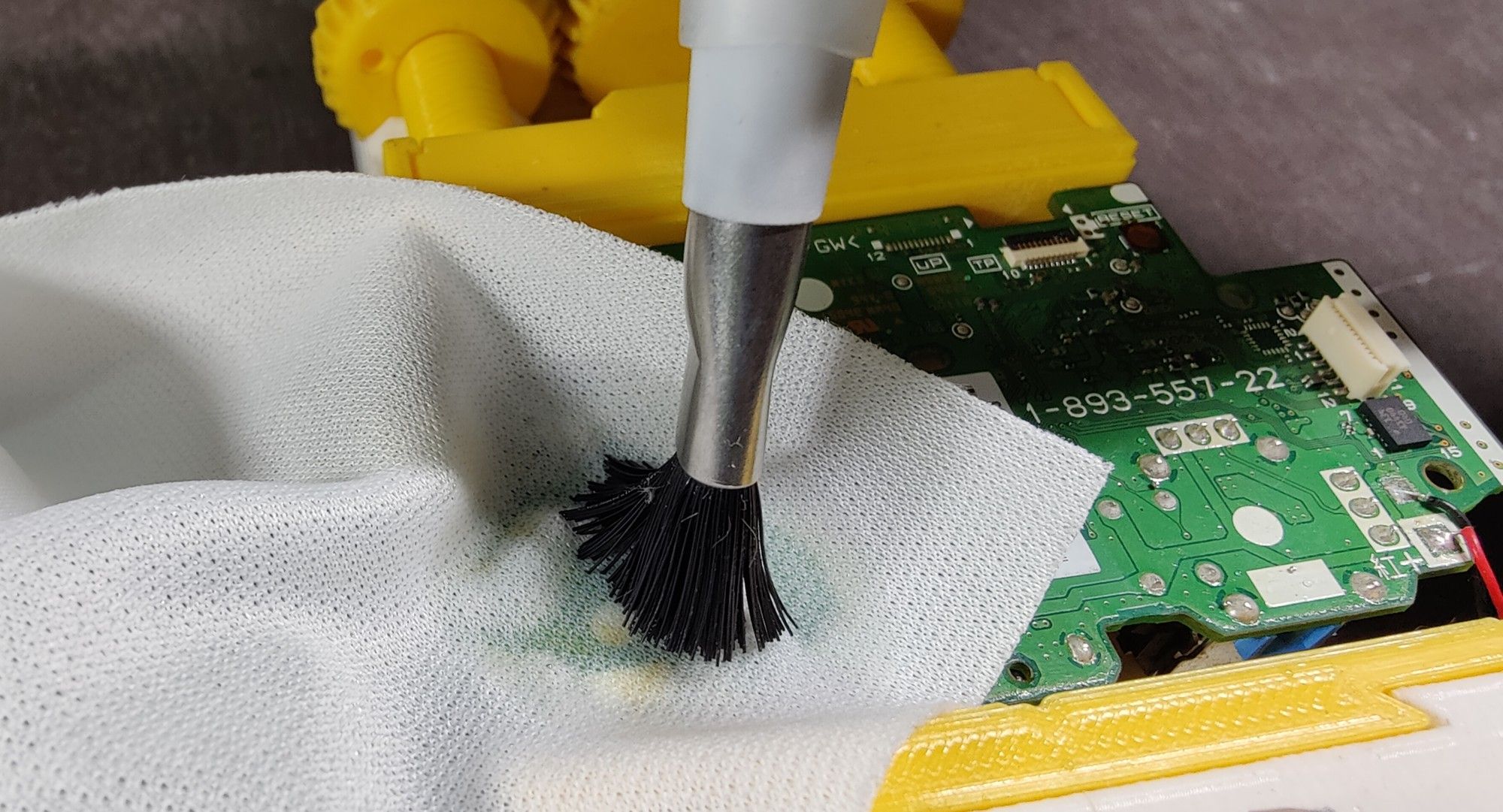

Step 12: Clean the Flux Residue off the PCB

Although flux makes soldering piece of cake, it also creates a sticky mess that promotes corrosion by trapping dust and wet over time. In an increasing society of effectiveness, high-purity IPA, acetone, or specialized flux removers are best suited for the job.

IPA and acetone are more effective if you employ a accident dryer to oestrus up (do not exceed 175°F) the PCB.

Avoid spreading the flux everywhere on the PCB. Instead, place cleanroom wipes (lint-complimentary, static-resistant cloth or coffee filter newspaper works too) on the rest and dab information technology up with your flux cleaner of pick. You want the material to soak up the flux instead of smearing it around.

Make clean both sides of the PCB.

Step 13: Solder the Replacement

Position the replacement analog stick assembly (or only the potentiometers) and record it down with masking tape to concord it in place.

Don't forget to add flux prior to soldering. Call up to bridge both the lead and the circular pad with the tip of your fe before introducing solder to grade a articulation. Solder is attracted to heat, so just heating the pad or the pb volition lead to cold joints.

Soldering is easier than desoldering, so the four structural joints volition be a fleck challenging, but not impossible if yous stick to our recommended soldering equipment.

Step xiv: Clean Flux Residue Again

This is especially important when the flux or solder used contains activated agents. These can crusade corrosion over time if left uncleaned.

We're Finally Done!

Reassembly is the opposite of disassembly. Trace back the disassembly steps and you'll have a working DualShock 4 wireless controller that'due south ready for action.

MUO has affiliate and sponsored partnerships, then nosotros receive a share of the revenue from some of your purchases. This won't touch on the price you pay and helps us offer the best product recommendations.

Dualshock 4 Analog Stick Drifting,

Source: https://www.makeuseof.com/ps4-controller-drift/

Posted by: sicklerarownevally1966.blogspot.com

0 Response to "Dualshock 4 Analog Stick Drifting"

Post a Comment